Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod Lorem ipsum dolor sit amet consectetur adipiscing elit, sed do eiusmod lorem ipsum

Eco-Friendly Options in Plastic Packaging Buckets

Comprehensive analysis of bird seed bucket production in 2024, covering materials, manufacturing processes, safety standards, and sustainability practices. Essential guide for industry professionals and manufacturers.

Production Standards: Animal Feed Bucket Manufacturing

Creating your own jewelry box is a deeply satisfying and creative project that results in a personalized storage solution for your treasured pieces.

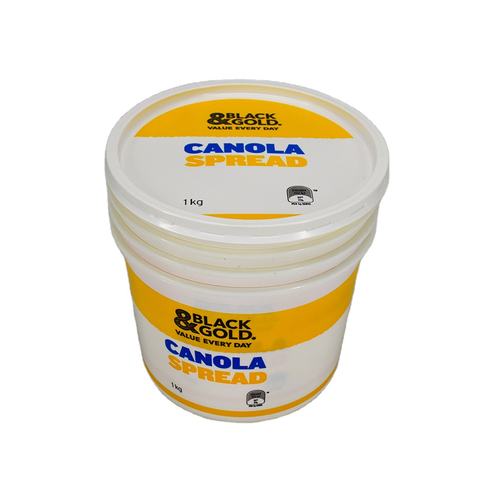

Quality Standards: Food-Grade Bucket Production

Discover comprehensive quality standards for food-grade bucket production, from material selection to certification requirements. Learn about manufacturing controls, size standards, testing protocols, and customization options. Includes essential FAQs about food-grade packaging solutions, perfect for manufacturers and buyers seeking industry insights.