Integração da linha de produção: Fabrico de baldes quadrados

Análise exaustiva da produção de baldes de sementes para aves em 2024, abrangendo materiais, processos de fabrico, normas de segurança e práticas de sustentabilidade. Guia essencial para profissionais e fabricantes do sector.

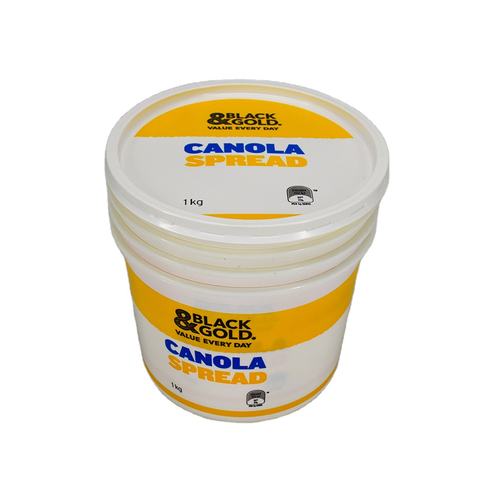

Fabrico por grosso de baldes para embalagens de plástico para uso alimentar, químico e industrial

Fabricante líder de baldes para embalagens de plástico de alta qualidade que oferece tamanhos personalizáveis de 150 ml a 60 litros. Materiais de qualidade alimentar aprovados pela FDA, design à prova de fugas e opções de impressão IML. Perfeito para embalagens de produtos alimentares, químicos e industriais. Encomendas por grosso a granel disponíveis com envio global.

Linha profissional de fabrico de baldes de plástico para serviço pesado com capacidade de 200 ml a 60 l

Fabricante líder de baldes de plástico de alta qualidade para trabalhos pesados, com sistemas de controlo de qualidade automatizados, materiais PP/HDPE de qualidade alimentar e designs personalizáveis. Ideal para embalagens de alimentos, produtos químicos industriais e armazenamento comercial. Disponível em tamanhos de 200 ml a 60 l com vedantes herméticos e pegas duradouras.